- Cat Military Equipment Line

- CAT 930K Air-Deployable Wheel Loader

- CAT 420 Air-Deployable Backhoe Loader

- CAT 323 Hydraulic Excavator

- CAT 966H Wheel Loader with Optional Armor Solutions

- CAT 279D3 Compact Track Loader with Optional Armor Solutions

- CAT D9R Bulldozer with Optional Armor Solutions

- CAT D7R-II Medium Military Dozer

- CAT 930K ATFL All-Terrain Forklift (10K / 13K)

- CAT 930/938 RTFL Rough-Terrain Forklifts (12K / 16K)

- CAT 120M AWD Motor Grader

Caterpillar Inc., a name synonymous with heavy machinery and industrial equipment, has a significant presence in the military sector. From robust construction equipment adapted for military use to innovative solutions designed to support operations in the most challenging environments, Caterpillar military equipment line includes modified versions of their renowned construction machinery, tailored to meet the rigorous demands of military applications.

U.S. Army acquisition orders often necessitate significant engineering design modifications. These can include armored cabs, blackout lighting, military-style lift and tie-down gear to meet MIL-STD-209K compliance, and accommodations for helicopter sling loading and aerial delivery via parachute. CAT’s mission-focused equipment solutions are designed to help accomplish the most challenging tasks in the most adverse and diverse environments.

Cat Military Equipment Line

Caterpillar is dedicated to maximizing operator safety and efficiency, both on the front line and behind it. The Cat military equipment solutions deliver the industry’s most powerful and reliable equipment that personnel rely on every day for their critical operations. In this review of Caterpillar military equipment, we will explore the capabilities, design features, and roles of key machinery in CAT’s military lineup.

CAT 930K Air-Deployable Wheel Loader

A versatile and air-deployable wheel loader designed for quick deployment and efficient operation in various terrains.

CAT 930K Wheel Loader with Bucket / with Material Handling Arm / with Forks

| Category | Specification |

|---|---|

| Engine Model | Cat® C7.1 ACERTTM |

| Maximum Gross Power | |

| – Maximum Engine Speed | 1,800 rpm |

| – ISO 14396:2002 | 160 hp / 119 kW |

| – ISO 14396:2002 (DIN) | 162 hp / 121 kW |

| Rated Net Power @ 1,800 rpm | |

| – SAE J1349:2011 (Min Fan Speed) | 155 hp / 116 kW |

| – ISO 9249:2007 (Min Fan Speed) | 154 hp / 115 kW |

| – ISO 9249 (DIN) | 156 hp / 117 kW |

| Maximum Gross Torque | |

| – ISO 14936:2002 | 572 ft-lb / 775 Nm |

| Maximum Net Torque @ 1,400 rpm | |

| – SAE J1349:2011 (Min Fan Speed) | 559 ft-lb / 757 Nm |

| – ISO 9249:2007 (Min Fan Speed) | 555 ft-lb / 752 Nm |

| Displacement | 428 in³ / 7.01 L |

| Bore | 4.13 in / 105 mm |

| Stroke | 5.3 in / 135 mm |

| Transmission | |

| Forward | |

| – 1st Gear | 0.6-8 mph / 1-13 km/h |

| – 2nd Gear | 8 mph / 13 km/h |

| – 3rd Gear | 17 mph / 27 km/h |

| – 4th Gear | 25 mph / 40 km/h |

| Reverse | |

| – 1st Gear | 0.6-8 mph / 1-13 km/h |

| – 2nd Gear | 8 mph / 13 km/h |

| – 3rd Gear | 17 mph / 27 km/h |

| – 4th Gear | 25 mph / 40 km/h |

| Service Refill Capacities | |

| Fuel Tank | 51.5 gal / 195 L |

| Cooling System | 8.5 gal / 32 L |

| Crankcase | 5.2 gal / 19.5 L |

| Transmission | 2.2 gal / 8.5 L |

| Differentials and Final Drives | |

| – Front | 6.9 gal / 26 L |

| – Rear | 6.6 gal / 25 L |

| Hydraulic System – Including Tank | 43.6 gal / 165 L |

| Hydraulic Tank | 23.8 gal / 90 L |

| Cab | |

| ROPS | SAE J1040 MAY94, ISO 3471:1994 |

| FOPS | SAE J/ISO 3449 APR98 Level II, ISO 3449:1992 Level II |

| Sound Pressure Level | 78 dB(A) (ISO 6396:2008) |

Measurements taken with cab doors and windows closed and at 70% of maximum engine cooling fan speed.

CAT 420 Air-Deployable Backhoe Loader

A robust and air-deployable backhoe loader that combines digging, trenching, and material handling capabilities, making it ideal for diverse military applications.

CAT 420 Backhoe Loader Specs:

| Category | Specification |

|---|---|

| Engine Model |

Cat® 3054C Mechanically Turbocharged |

| Gross Power | |

| SAE J1995 | 101 hp / 75 kW |

| ISO 14396 | 94 hp / 70 kW |

| Rated Net Power @ 2,200 rpm | |

| SAE J1349 | 94 hp / 70 kW |

| ISO 9249 | 95 hp / 71 kW |

| Net Peak Power @ 2,200 rpm | |

| SAE J1349 | 94 hp / 70 kW |

| ISO 9249 | 95 hp / 71 kW |

| Bore | 4.13 in / 105 mm |

| Stroke | 5 in / 127 mm |

| Displacement | 268 in³ / 4.4 L |

| Net Torque Rise @ 1,400 rpm | 31% |

| Net Peak Torque | 293 ft-lb / 397 Nm |

| No De-Rating Required Up To | 7,500 ft / 2286 m |

| Transmission | |

| Auto Shift Transmission Forward | |

| – 1st | 3.7 mph / 5.9 km/h |

| – 2nd | 5.8 mph / 9.4 km/h |

| – 3rd | 7.6 mph / 12.3 km/h |

| – 4th | 12.2 mph / 19.6 km/h |

| – 5th | 16.8 mph / 27.1 km/h |

| – 6th | 25.5 mph / 41 km/h |

| Auto Shift Transmission Reverse | |

| – 1st | 3.7 mph / 5.9 km/h |

| – 2nd | 7.6 mph / 12.3 km/h |

| – 3rd | 16.8 mph / 27.1 km/h |

| Axle Rating | |

| Front Axle – 4WD | |

| Static | 51,808 lb / 23,500 kg |

| Dynamic | 19,841 lb / 9,000 kg |

| Rear Axle | |

| Static | 58,422 lb / 26,500 kg |

| Dynamic | 22,046 lb / 10,000 kg |

| Hydraulic System | |

| Type | Closed Center |

| Pump Type | Variable Flow, Axial Piston |

| Pump Capacity @ 2,200 rpm | 49.4 gpm / 187 Lpm |

| System Pressure – Backhoe | 3,626 psi / 25000 kPa |

| System Pressure – Loader | 3,626 psi / 25000 kPa |

| Service Refill Capacities | |

| Cooling System w/ AC | 4.8 gal / 18 L |

| Fuel Tank | 42.3 gal / 160 L |

| Engine Oil w/ Filter | 2.4 gal / 9 L |

| Transmission – AutoShift AWD | 5 gal / 19 L |

| Rear Axle | 42 gal / 160 L |

| Planetaries | 0.4 gal / 1.7 L |

| Front Axle – 4WD | 2.9 gal / 11 L |

| Planetaries | 0.2 gal / 0.7 L |

| Hydraulic System | 25.1 gal / 95 L |

| Hydraulic Tank | 11.1 gal / 42 L |

| Tires | |

| Front | 340 / 80-18 |

| Rear | 40 / 80-24 |

| Weights | |

| Operating Weight | 17,588 lb / 7987 kg |

| Minimum Weight | 16,279 lb / 7384 kg |

| Maximum Weight (ROPS Capacity) | 24,251 lb / 11,000 kg |

| Cab, ROPS/FOPS | 320 lb / 145 kg |

| AutoShift Transmission | STD / STD |

| Ride Control | 33 lb / 15 kg |

| Air Conditioning | 99 lb / 45 kg |

| All-Wheel Drive | STD / STD |

| MP Bucket (1.25 yd³ / 0.96 m³) | |

| – with Fold-Over Forks | 2,107 lb / 915 kg |

| – without Fold-Over Forks | 1,642 lb / 745 kg |

| Loader, Quick Coupler | 540 lb / 245 kg |

| Counterweights – Option 1 | 255 lb / 115 kg |

| Counterweights – Option 2 | 530 lb / 240 kg |

| Counterweights – Option 3 | 1,015 lb / 460 kg |

| Steering | |

| Type | Front Wheel |

| Axle Oscillation | Hydrostatic |

| Turning Circle – AWD | |

| Outside, Front Wheels | 26.9 ft / 8.21 m |

| Outside, Widest Loading Bucket | 35.25 ft / 10.75 m |

CAT 323 Hydraulic Excavator

A powerful hydraulic excavator that provides superior digging performance and versatility, crucial for military construction and excavation tasks.

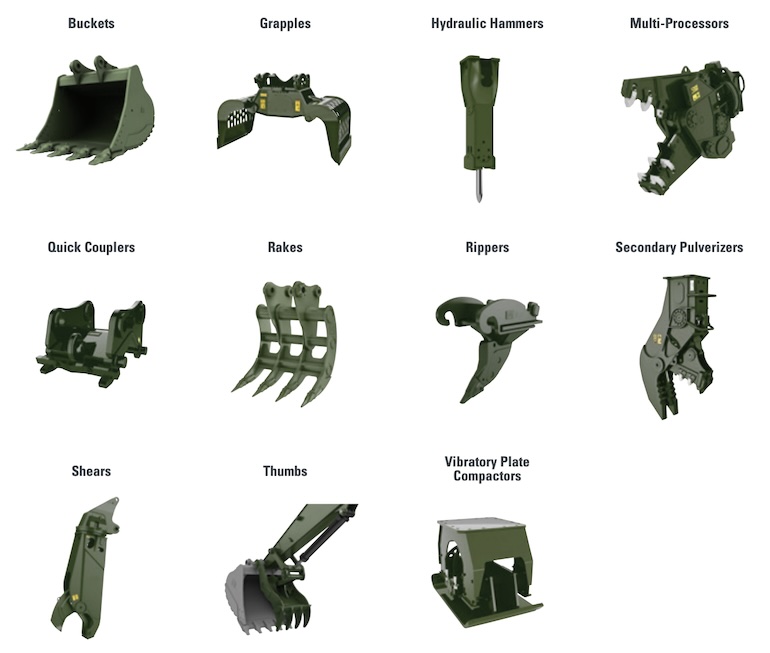

As operating environments and tasks change, easily expand the capability and performance of the 323 HEX.

The full line of Cat military excavator attachments is specifically designed to fit the weight and horsepower of Cat Excavators, delivering the highest performance, safety and stability for every operation.

CAT 323 Military Excavator Specs:

| Category | Specification |

|---|---|

| Engine Model | Cat® C7.1 ACERT™ |

| Net Power – ISO 9249 | 157 hp / 117 kW |

| Net Power – SAE J1349 | 157 hp / 117 kW |

| Gross Power – ISO 14396/SAE J1995 | 158 hp / 118 kW |

| Bore | 4 in / 105 mm |

| Stroke | 5 in / 135 mm |

| Displacement | 428 in³ / 7.01 L |

| Emission Standards | Meets Tier 3 emission standards |

| Altitude Capability | Recommended up to 14,760 ft / 4500 m, power derate above 9,840 ft / 3000 m |

| Power Rating | Advertised power at 1,800 rpm with fan, air cleaner, muffler, and alternator |

| Engine RPM | |

| Operation RPM | 1,650 rpm |

| Travel RPM | 1,800 rpm |

| Hydraulic System | |

| Main System – Maximum Flow | 113 gpm / 429 Lpm (57 x 2 pumps / 215 x 2 pumps) |

| Maximum Pressure – Equipment – Normal | 5,075 psi / 35,000 kPa |

| Maximum Pressure – Equipment – Lift Mode | 5,510 psi / 38,000 kPa |

| Maximum Pressure – Travel | 4,974 psi / 34,300 kPa |

| Maximum Pressure – Swing | 3,886 psi / 26,800 kPa |

| Boom Cylinder – Bore | 5 in / 120 mm |

| Boom Cylinder – Stroke | 50 in / 1260 mm |

| Stick Cylinder – Bore | 6 in / 140 mm |

| Stick Cylinder – Stroke | 59 in / 1504 mm |

| Bucket Cylinder – Bore | 5 in / 120 mm |

| Bucket Cylinder – Stroke | 43 in / 1104 mm |

| Swing Mechanism | |

| Swing Speed | 11.25 rpm |

| Maximum Swing Torque | 54,440 ft-lb / 74 Nm |

| Service Refill Capacities | |

| Fuel Tank | 86.6 gal / 345 L |

| Cooling System | 6.6 gal / 25 L |

| Engine Oil | 6.6 gal / 25 L |

| Swing Drive – Each | 1.3 gal / 5 L |

| Final Drive – Each | 1.3 gal / 5 L |

| Hydraulic System – Including Tank | 61.8 gal / 234 L |

| Hydraulic Tank | 30.4 gal / 115 L |

| Drive | |

| Maximum Gradeability | 35° / 70% |

| Maximum Travel Speed | 3.5 mph / 5.7 km/h |

| Maximum Drawbar Pull | 45,614 ft-lb / 203 Nm |

| Track | |

| Standard Track Shoe Width | 24 in / 600 mm |

| Number of Shoes (Each Side) | 49 |

| Number of Track Rollers (Each Side) | 8 |

| Number of Carrier Rollers (Each Side) | 2 |

| Weights | |

| Operating Weight | 54,000 lb / 24,500 kg |

| HD Reach Boom | 18.6 ft / 5.7 m |

| HD Stick | 9.5 ft / R2.9 m |

| HD Bucket | 1.54 yd³ / 1.18 m³ |

| HD Triple Grouser Shoes | 24 in / 600 mm |

| Counterweight | 6 t / 5.4 mt |

| Ground Pressure | 7.20 psi / 49.70 kPa |

| Standards | |

| Brakes | ISO 10265:2008 |

| Cab/FOGS | ISO 10262:1998 |

| Cab/ROPS | ISO 12117-2:2008 |

| External Sound Level | ISO 6395:2008 (100 dB(A)) |

| Internal Sound Level | ISO 6396:2008 (70 dB(A)) |

| Hearing protection may be needed with an open operator station and cab, or in a noisy environment. |

CAT 966H Wheel Loader with Optional Armor Solutions

This loader is crucial for heavy material handling and construction tasks, and its armored configuration provides additional protection, allowing it to operate effectively in combat zones.

Cat 966H Loader Military Modifications:

- C17/C5 air transportable;

- Removable cab for transport;

- NATO slave receptacle;

- MIL-STD-209 lift and tie down provisions;

- Fresh water fordable to 20 in/508 mm depth;

- Blackout lighting system;

- Rifle bracket;

- Storage – provisions for MOPP gear;

- Cold start aid for -25° F (ether);

- Military towing lugs;

- Vandalism protection;

- Keyless engine start switch;

- Military oil sampling valves;

- Fire extinguisher;

- Brush guards for lights;

- CARC paint OPTIONAL;

- Hydraulic broom;

- Foam-filled tires;

- Pallet forks;

- Machine armor package;

- Two-person armored cab

CAT 279D3 Compact Track Loader with Optional Armor Solutions

The CAT 279D3 compact track loader with optional armor, designed for maneuverability and protection in confined and challenging terrains.

Armored CAT 279D3 CTL Attachments:

- Auger;

- Dozer;

- Blades;

- Backhoe;

- Hammers;

- General Purpose (GP) Bucket;

- Multi Purpose (MP) Bucket;

- Vibratory Compactor;

- Pallet Forks;

- Cold Planer;

- Broom;

- Wheel Saw;

- Trenchers;

- Hydraulic Boom;

- Grapple Arm.

Cat Remote Control (Portable operator console, Range 1,312.34 ft/400 m LOS, Frequency 900 MHz or 2.4 GHz, Remote control indicator lights up and horn sounds during training, Conceal mode for tactical operations).

Military CAT 279D3 CTL Specs

| Category | Specification |

|---|---|

| Engine Model |

Cat® C3.3B Turbocharged Diesel |

| Gross Power SAE J1995 (hp/kW) | 74.3 / 55.4 |

| Net Power SAE 1349 (hp/kW) | 71.8 / 53.6 |

| Net Power ISO 9249 (hp/kW) | 72.6 / 54.41 |

| Peak Torque @ 1,600 rpm SAE J1995 (lb-ft/Nm) | 195 / 265 |

| Displacement (in³/L) | 203 / 3.3 |

| Stroke (in/mm) | 4.7 / 120 |

| Bore (in/mm) | 3.7 / 94 |

| Rated Capacity | |

| Tipping Load (lb/kg) | 6,345 / 2878 |

| 35% Tipping Load (lb/kg) | 2,220 / 1007 |

| 50% Tipping Load (lb/kg) | 3,170 / 1438 |

| With Optional Counterweight (lb/kg) | 3,390 / 1538 |

| Breakout Force, Tilt Cylinder (lb/kg) | 7,285 / 3304 |

| Ground Contact Area (17.7 in / 450 mm Track) | 2,272 in² / 1.47 m² |

| Ground Pressure (17.7 in / 450 mm Track) | 4.4 psi / 30.4 kPa |

| Service Refill Capacities | |

| Cooling System (gal/L) | 3.7 / 14 |

| Engine Crankcase (gal/L) | 3 / 11 |

| Fuel Tank (gal/L) | 27.7 / 105 |

| Hydraulic System (gal/L) | 13.7 / 52 |

| Hydraulic Tank (gal/L) | 10.3 / 39 |

| Weights | |

| Without Armor (lb/kg) | 9,893 / 4487 |

| With Armor (lb/kg) | 10,988 / 4984 |

| Rated Capacity (lb/kg) | 2,935 / 1331 |

| Power Train | |

| Travel Speed (Forward or Reverse) | |

| One Speed (mph/km/h) | 4.5 / 7.2 |

| Two Speed (mph/km/h) | 8.3 / 13.3 |

| Hydraulic System | |

| – Hydraulic Flow (Standart) | |

| Loader Hydraulic Pressure (psi/kPa) | 3,335 / 23,000 |

| Loader Hydraulic Flow (gpm/Lpm) | 23 / 86 |

| Hydraulic Power, Calculated (hp/kW) | 44 / 33 |

| – Hydraulic Flow (High Flow XPS) | |

| Maximum Loader Hydraulic Pressure (psi/kPa) | 4,061 / 28,000 |

| Maximum Loader Hydraulic Flow (gpm/Lpm) | 32 / 121 |

| Hydraulic Power, Calculated (hp/kW) | 76 / 57 |

CAT D9R Bulldozer with Optional Armor Solutions

The D9R Bulldozer is a powerhouse in the CAT military equipment lineup, with optional armor solutions for enhanced protection. Known for its strength and durability, the D9R is capable of performing demanding tasks such as clearing obstacles, constructing defensive positions, and supporting logistics operations.

CAT D7R-II Medium Military Dozer

The CAT D7R-II military dozer is designed for medium-duty tasks in military operations. Its robust construction and advanced technology enable it to perform efficiently in a variety of terrains and conditions. It is ideal for tasks such as road building, site preparation, and obstacle removal.

CAT D7R-II dozer armor protection solutions:

The armored crew protection kit (CPK) on the D7R-II provides 360º protection for operators inside the cab. Its emergency egress hatch gives operators the ability to quickly exit the cab, while providing rescue personnel critical access to those inside. Transparent armor provides a wide field of view of the machine and surrounding areas. Cat armor protection solutions give operators the scalability they need to adapt to changing environments and conditions.

- Multiple Armor Packages

– 1-person or 2-person CPK

– Machine Armor Protection (MAP) for critical machine automotive components - CPK Protection Levels Available

– STANAG 4569 Annex A Level 2 – Annex B Level 4

– STANAG 4569 Annex A Level 3 – Annex B Level 4 - MAP Protection Levels Available

– STANAG 4569 Annex A Level 2 – Annex B Level 3

– STANAG 4569 Annex A Level 3 – Annex B Level 3

CAT D7R-II dozer military modifications:

- SU Blade;

- Winch (optional);

- Multi-Shank Ripper (optional);

- C17 and C5 air transportable;

- M870 and HET trailer transportable;

- Armored cab with CPK (optional): 1-person or 2-person;

- Removable cab and ROPS for transport;

- NATO start receptacle;

- Elevated sprocket undercarriage;

- MIL-STD-209K lift and tie down provisions: machine, cab, ROPS, push arms and blade;

- Fresh water fordable to 30 in/762 mm depth (standard);

- CARC or special paint;

- NATO-STANAG-4019 towing lugs;

- Keyless engine start switch;

- Military oil sampling valves;

- Fire extinguisher;

- Rifle bracket;

- Remote control (optional);

- Vision system (optional): control box and 4 cameras (magnet or bolt mounted) – 2.4 GHz IP radios range 6,561.68 ft/2000 m LOS with video and sound. Vision system tablet displays 4-camera view: front/rear/left/right + 1 additional camera for custom views (.

CAT 930K ATFL All-Terrain Forklift (10K / 13K)

All-terrain forklifts designed for rugged environments, ensuring efficient material handling in diverse military settings.

Perform every task with the highest efficiency. Handle the machine and critical cargo with complete control. Cat® 930K military all-terrain forklifts (ATFLs) are engineered to deliver maximum capacity & productivity, even when underfoot conditions change from paved to unimproved surface.

| Specification | 10K Variant | 13K Variant |

|---|---|---|

| Machine Width (in/mm) | 100 / 2540 | 100 / 2540 |

| Operating Weight (lb/kg) | 26,653 / 12,090 | 29,288 / 13,285 |

| Rated Load (lb/kg) | 10,000 / 4,536 | 13,000 / 5,897 |

| Rated Operating Capacity at Load Center | ||

| – lb @ in | 10,000 @ 48 | 13,000 @ 54 |

| – kg @ mm | 4,536 @ 1219 | 5,897 @ 1372 |

| Turning Radius (in/mm) | ||

| – Over Tires | 213 / 5418 | 270 / 6860 |

| – Over Forks | 229 / 5817 | 280 / 7116 |

| Air Transportable ATTLA-Cert (lb/kg) | ||

| – Front Axle | 12,149 / 5511 | 12,750 / 5783 |

| – Rear Axle | 12,433 / 5640 | 12,846 / 5827 |

| Drive-On Weight for 13,000 lb/5,896.70 kg Axle Load for Air Transport (lb/kg) | 24,582 / 11,151 | 25,596 / 11,610 |

When fully loaded, Cat 930K military ATFLs allow operators to efficiently lift and haul cargo up to 10,000 lbs (4,536kg) with the 10K variant or 13,000 lbs (5,897kg) with the 13K variant. Operating with the closed center hydraulic system and work-ready 75 inches (1,905 mm) of lift height, Cat all-terrain forklift precisely manage every load on and off aircraft.

CAT 930/938 RTFL Rough-Terrain Forklifts (12K / 16K)

The CAT 930/938 RTFL Rough-Terrain Forklifts are engineered for rugged environments. With 12K and 16K load capacities, these forklifts are designed to manage heavy materials and equipment in challenging terrains, ensuring efficient logistical support in military operations.

CAT 930/938 Rough-Terrain Forklifts Specs:

| Specification | 12K Variant | 16K Variant |

|---|---|---|

| Machine Width (in/mm) | 101 / 2561 | 106 / 2693 |

| Machine Length (in/mm) | 337 / 8549 | 337 / 8549 |

| Operating Weight (lb/kg) | 29,011 / 13,159 | 33,986 / 15,416 |

| Operating Axle Load | ||

| – Front Axle (lb/kg)** | 12,070 / 5475 | 13,402 / 6079 |

| – Rear Axle (lb/kg)** | 16,345 / 7414 | 20,585 / 9337 |

| Rated Operating Capacity @ 48″ Load Center (lb/kg) | 12,000 / 5443 | 16,000 / 7257 |

| Drive-On Length for Air Transport (in/mm) | TBD | 337 / 8549 |

| Drive-On Height for Air Transport (in/mm) | TBD | 131 / 3340 |

| Drive-On Weight for Air Transport (lb/kg) | TBD | 33,986 / 15,416 |

| Air Transportable ATTLA-Certified | ||

| – Front Axle (lb/kg)** | TBD | 13,288 / 6040 |

| – Rear Axle (lb/kg)** | TBD | 20,042 / 9110 |

CAT 120M AWD Motor Grader

The CAT 120M AWD Motor Grader is a key asset for maintaining military infrastructure. Its all-wheel drive (AWD) capability provides enhanced traction and control, making it suitable for grading and maintaining roadways and airstrips under various conditions.

CAT 120M military motor grader specifications:

| Operating Specifications | 120M AWD Motor Grader |

|---|---|

| Engine | |

| Model | Cat® C6.6 ACERTTM |

| Displacement (in3/L) | 403 / 6.6 |

| Bore (in/mm) | 4.13 / 105 |

| Stroke (in/mm) | 4.92 / 125 |

| Number of Cylinders | 6 |

| Speed @Rated Power (rpm) | 2000 |

| VHP Plus Maximum Torque (ft-lb/Nm) | 690 / 859 |

| VHP Plus Torque Rise | 40% |

| VHP Plus Net Power (hp/kW) | 138 – 173 / 103-129 |

| – Forward – 1st (hp/kW) | 138 / 103 |

| – 2st (hp/kW) | 143 / 107 |

| – 3st (hp/kW) | 148 / 110 |

| – 4st (hp/kW) | 153 / 114 |

| – 5st (hp/kW) | 158 / 118 |

| – 6st (hp/kW) | 163 / 121 |

| – 7st (hp/kW) | 168 / 125 |

| – 8st (hp/kW) | 173 / 129 |

| – Reverse – 1st (hp/kW) | 138 / 103 |

| – 2st (hp/kW) | 143 / 107 |

| – 3st – 6st (hp/kW) | 148 / 110 |

| PowerTrain | |

| Forward/Reverse Gears | 8 Forward / 6 Reverse |

| Transmission | Direct Drive, Power Shift, Countershaft |

| Brakes | |

| – Service | Multiple Oil-Disc |

| – Parking | Multiple Oil-Disc |

| – Secondary | Dual Circuit Control System |

| All-Wheel Drive System | |

| – Motor Type | 2 Infinitely Variable Axial Piston |

| – Pump Type | 2 Variable Piston |

| – Operational Gears | Forward = 1-7, Reverse = 1-5 |

| Hydraulic System | |

| – Type | Electro-hydraulic, Load Sensing, Closed Center |

| – Pump Type | Variable Piston |

| – Pump Capacity @2,150 rpm (gpm/Lpm) | 40 / 151 |

| – Maximum System Pressure (psi/kPa) | 3,500 / 24,100 |

| – Standby Pressure (psi/kPa) | 450 / 3,100 |

| Operating Specs | |

| – Top Speed – Forward (mph / km/h) | 27.7 / 44.5 |

| – Top Speed – Reverse (mph / km/h) | 23.5 / 37.8 |

| – Turning Radius, Outside Front Tires (ft/m) | 37 / 11.3 |

| – Steering Range – Left/Right | 42° |

| – Articulation Angle – Left/Right | 20° |

| – Forward – 1st (mph / km/h) | 2.4 / 3.9 |

| – 2st (mph / km/h) | 3.3 / 5.3 |

| – 3st (mph / km/h) | 4.75 / 7.6 |

| – 4st (mph / km/h) | 6.5 / 10.5 |

| – 5st (mph / km/h) | 10.2 / 16.4 |

| – 6st (mph / km/h) | 13.8 / 22.2 |

| – 7st (mph / km/h) | 19.0 / 30.6 |

| – 8st (mph / km/h) | 27.7 / 44.6 |

| – Reverse – 1st (mph / km/h) | 2.0 / 3.2 |

| – 2st (mph / km/h) | 3.8 / 6.1 |

| – 3st (mph / km/h) | 5.6 / 9.0 |

| – 4st (mph / km/h) | 8.6 / 13.8 |

| – 5st (mph / km/h) | 16.1 / 25.9 |

| – 6st (mph / km/h) | 23.5 / 37.8 |

| Service Refill Capacities | |

| Fuel Tank (gal/L) | 90 / 340 |

| Cooling System (gal/L) | 104. / 40 |

| Hydraulic System (gal/L) | 15.9 / 60 |

| Engine Oil (gal/L) | 41. / 15.5 |

| Trans. / Dif./ Final Drives (gal/L) | 13.2 / 50 |

| Tandem Housing – each (gal/L) | 16.9 / 61 |

| Front Wheel Spindle Bearing Housing (gal/L) | 0.1 / 0.5 |

| Circle Drive Housing (gal/L) | 1.8 / 7 |

| Frame | |

| Circle – Diameter (in/mm) | 60.2 / 1530 |

| Blade Beam Thickness (in/mm) | 1.4 / 35 |

| Drawbar | |

| – Height (in/mm) | 6 / 152 |

| – Width (in/mm) | 3 / 76.2 |

| – Thickness (in/mm) | 0.4 / 9.5 |

| – Yoke Bar Thickness (in/mm) | 0.75 / 19.1 |

| Front Frame Structure | |

| – Height (in/mm) | 10 / 254 |

| – Width (in/mm) | 10 / 254 |

| – Thickness (in/mm) | 0.6 / 16 |

| Front Axle | |

| – Height to Center (in/mm) | 22.5 / 572 |

| – Wheel Lean, Left/Right | 18° |

| – Total Oscillation Per Side | 32° |

| Tandems | |

| Height (in/mm) | 19.76 / 502 |

| Width (in/mm) | 6.76 / 171.7 |

| Sidewall Thickness | |

| – Inner (in/mm) | 0.5 / 12.7 |

| – Outer (in/mm) | 0.6 / 15.2 |

| Drive Chain Pitch (in/mm) | 1.8 / 45.7 |

| Wheel Axle Spacing (in/mm) | 59.5 / 1511 |

| Tandem Oscillation | |

| – Front Up | 15° |

| – Front Down | 25° |

| Scarifier | |

| Mid, V-Type | |

| Working Width (in/mm) | 46.6 / 1184 |

| Scarifying Depth, Maximum (in/mm) | 11.5 / 292 |

| Scarifier Shank Holders | 11 |

| Scarifier Shank Holder Spacing (in/mm) | 4.6 / 117 |

| Moldboard | |

| – Blade Width (ft/m) | 12 / 3.668 |

| – Moldboard – Height (in/mm) | 24 / 609.6 |

| – Moldboard – Thickness (in/mm) | 0.87 / 22 |

| – Arc Radius (in/mm) | 16.3 / 414 |

| – Throat Clearance (in/mm) | 4.9 / 123.9 |

| – Cutting Edge – Width (in/mm) | 6 / 152.4 |

| – Cutting Edge – Thickness (in/mm) | 0.6 / 15.2 |

| – End Bit – Width (in/mm) | 6 / 152.4 |

| – End Bit – Thickness (in/mm) | 0.6 / 15.2 |

| Blade Range | 25.8 / 655.3 |

| – Circle Centershift – Right (in/mm) | 25.8 / 655.3 |

| – Circle Centershift – Left (in/mm) | 25.8 / 655.3 |

| – Moldboard Sideshift – Right (in/mm) | 26 / 660.4 |

| – Moldboard Sideshift – Left (in/mm) | 20.1 / 510.5 |

| – Maximum Blade Position Angle | 90° |

| – Blade Tip Range – Forward | 40° |

| – Blade Tip Range – Backward | 5° |

| – Maximum shoulder reach outside of tires – Right (in/mm) | 75 / 1905 |

| – Maximum shoulder reach outside of tires – Left (in/mm) | 68.6 / 1742 |

| – Maximum Lift Above Ground (in/mm) | 16.8 / 427 |

| – Maximum Depth of Cut (in/mm) | 28.3 / 719 |

| Weights | |

| Gross Vehicle Weight – No Armor | |

| – Total (lb/kg) | 39,080 / 17,726 |

| – Front Axle (lb/kg) | 11,830 / 5,366 |

| – Rear Axle (lb/kg) | 27,250 / 12,360 |

| Gross Vehicle Weight – With Armor | |

| – Total (lb/kg) | 45,090 / 20,452 |

| – Front Axle (lb/kg) | 13,680 / 6,205 |

| – Rear Axle (lb/kg) | 31,410 / 14,247 |

Caterpillar has developed an extensive military training program to support the owners and operators of advanced equipment and engines. Cat’s program courses cover safety training, service training, and operator training to ensure that personnel are fully equipped to operate and maintain their machinery. These comprehensive training solutions are designed to enhance operational efficiency and equipment longevity.

Caterpillar military equipment exemplifies the company’s dedication to providing reliable, durable, and technologically advanced solutions for military applications. From hybrid electric dozers to autonomous machinery, CAT’s offerings are designed to enhance operational efficiency, reduce logistical burdens, and ensure the safety of military personnel.

I have previously seen Caterpillar D9 armored bulldozers used by the Israel Defense Forces. I wonder if the US Army is supplied with Cat D9 dozers?

No, Caterpillar supplies only CAT D7R-II Medium dozers to the US Army.