The Keestrack R3 Mobile Tracked Impact Crusher is a versatile and robust machine designed for high performance in a variety of applications. Engineered with innovative technology and built to the highest standards, the R3 combines powerful crushing capabilities with environmental consciousness, offering a sustainable zero-emission plug-in electric drive system. Its compact design ensures easy transportation and maneuverability across different job sites, making it a valuable asset for industries ranging from construction and demolition to quarrying and mining. With advanced safety features, high throughput capacity, and accessibility for maintenance, the Keestrack R3 sets a new benchmark for efficiency, reliability, and versatility in the mobile crushing sector.

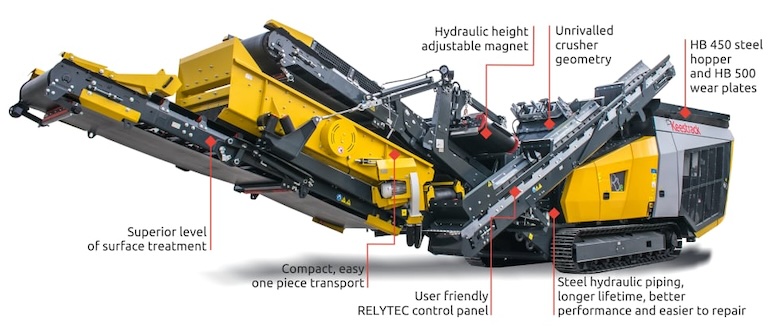

Its compact size and weight make it easy to transport without the need for special permits, ensuring convenience for operators. Capable of processing up to 250 tonnes per hour, the R3 is designed for high-efficiency crushing. The load-sensing hydraulic system significantly reduces fuel usage, contributing to its eco-friendly operation.

Keestrack R3 Key Features

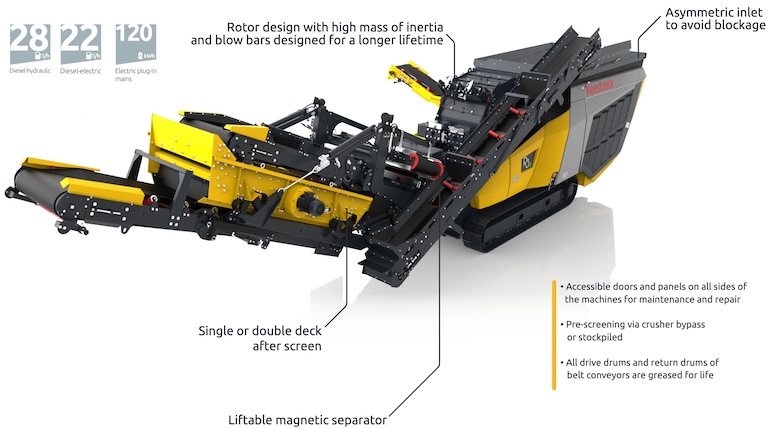

- Full Hybrid e-Version: The R3 is available in a full hybrid electric version, offering environmentally friendly operation with reduced emissions and lower operational costs.

- Transport and Mobility: The crusher weighs 27.5 tonnes in its base configuration and up to 32-33 tonnes with optional after screens. It is designed for easy transport without special permits, thanks to its compact dimensions (10,000 mm length, 3,200 mm height, and 2,550 mm width without after screens).

- Hopper and Feeder: The hopper has a capacity of 3.5 m³ (4.5 yd³), allowing for substantial feed volumes. Equipped with a vibrating feeder featuring a punched plate pre-screen (1,200 mm x 920 mm), ensuring efficient pre-sorting of material.

- Crushing Efficiency: The crusher has an inlet opening of 770 x 960 mm, accommodating large feed sizes. A superior rotor diameter of 1,100 mm provides significant crushing power. The machine can handle up to 250 tonnes per hour, making it suitable for high-volume operations.

- Optional Features: An optional third impact panel serves as a milling beam to produce high-value end products. Available with optional single or double deck after screens (3,100 x 1,400 mm), enhancing product separation and quality. An optional windsifter can be integrated for further material refinement.

- Hydraulic System: The load-sensing hydraulic system reduces fuel consumption by up to 25%, contributing to lower operating costs.

- Track Drive: The 2-speed track drive ensures smooth and efficient movement on the job site.

- Product Quality: The R3 is known for its high reduction ratio and superior product shape, delivering consistent and high-quality end products.

- Customization: A comprehensive list of options allows the R3 to be configured to specific application needs, enhancing its versatility.

Keestrack R3 Impact Crusher Specs

| Specification | Details |

|---|---|

| Capacity up to | 250 t |

| Weight | 27.5 t |

| Weight incl. single deck after screen | 30 t |

| Weight incl. double deck after screen | 33.2 t |

| Inlet opening | 770 x 960 mm |

| Hopper | 3.5 m³ |

| Feed hopper in HB450 and wear lining in HB 450 & 500 | • |

| Hydraulic foldable hopper walls | / |

| Transport Dimensions | |

| Transport L x W x H (mm) | 10000 x 2550 x 3200 mm |

| Transport L x W x H (mm) 1-deck | 12900 x 2550 x 3200 mm |

| Transport L x W x H (mm) 2-deck | 13260 x 2550 x 3200 mm |

| Loading height = 3200 mm | |

| Loading width (back) | 2400 mm |

| Side loading length | 3450 mm right, 2750 mm left |

| Wear lining | HB 450 welded/ HB 500 bottom |

| Vibrating feeder with pre-screen,L x W | 3700 mm x 920 mm |

| Pre-screen scalper, L x W | 1200 mm x 920 mm |

| Screened fraction either in crusher bypass or separately stockpiled | • |

| Vibrating feeder, L x W | Not applicable |

| Independent vibrating Double Deck pre-screen | Not applicable |

| Double deck pre-screen, L x W top deck | Not applicable |

| Double deck pre-screen, L x W bottom deck | Not applicable |

| Under screen conveyor: Reversible, to crusher bypass or to side conveyor | / |

| Fine fraction either in crusher bypass or separately stockpiled | Not applicable |

| Intermediate fraction in crusher bypass | Not applicable |

| Intermediate fraction either in crusher bypass or separately stockpiled | Not applicable |

| Turnable heavy duty bar for edge protection in inlet | • |

| Impact Crusher | |

| Weight of impact crusher (excl. milling beam) | 8.5 t |

| Inlet opening | 770 x 960 mm |

| Rotor width | 920 mm |

| Rotor diameter | 1100 mm |

| Rotor weight (excl. Bearings) | 3.2 t |

| Impact aprons | 2 pcs |

| Hydraulic release system inlet area via remote control | • |

| Hydraulic setting of aprons, turning spindle for fixation of the back stop. Spring force adjustments and shimming plates fixation | • |

| Standard access to crusher house | right side |

| Vibrating discharge feeder (L x W) | / |

| Main conveyor belt (L x W) & (discharge height) | 8100 mm x 1000 mm (3310 mm) |

| Main conveyor belt height adjustable at discharge and lowerable mechanism | • |

| Main conveyor hydraulic foldable for transport | • |

| Track-unit: Length, total width, track shoe width | 3310, 2300, 400 mm |

| 2-speed track drive | 1,1 km/h and 2 km/h |

| Drop-off engine | / |

| Engine unit(s), indication, sometimes more optional engines | 202 kW @ 1500 RPM, 222 kW @1800 RPM |

| Control: PLC – IP 67 LCD screen 7″ & remote control | |

| Smart sequential auto start/stop from remote control | • |

| Safety protection with special key system, emergency stops, machine stop at remote, protected doors during operation and other safety feature | • |

| All drive drums and return drums of belt conveyors are greased for life | • |

| Patented tilting chassis for increased maintenance access and to increase feed capacity if needed | / |

| Available drive systems | |

| – Diesel/hydraulic drive | • |

| – Rotor direct driven by engine, electric driven components | / |

| – e-drive Diesel/hybrid, electric plug-in & plug-out | • |

| – ZERO drive (no combustion engine, plug-in electric) | • |

Keestrack R3 Impact Crusher Options

| Feeding, pre-screen & crushing | |

|---|---|

| Hopper extensions | 5 m³ |

| Screen media pre-screen | Range of punched plates, screen plates and Zig zag-shaped or blind plate |

| Stockpiling Side belt conveyor from pre-screen L x W (discharge height) | 3900 x 500 mm (2595 mm) |

| Milling beam | • |

| Deviation plates | • |

| Several quality blow bars | • |

| Swiveling arm and hoist to change blow bars | • |

| Frequency inverter for crusher drive on e-version | • |

| After screen | |

| Single deck after screen: L x W, incl oversize, recycling and fines conveyor | 3100 x 1400 mm |

| Oversize stockpile conveyor L x W (discharge height) | 4400 x 500 mm (2520 mm) |

| 2- deck after screen: incl oversize, recycling and fines conveyor for closed circuit processing. After screen unit can be disassembled easy by fast connectors and can be placed on support legs | • |

| Top deck, L x W | 3100 x 1400 mm |

| Bottom deck, L x W | 3100 x 1400 mm |

| Screen media after screen | Wire mesh / square mesh / Harp screen |

| Middle fraction stockpile conveyor, L x W (discharge height) | 6000 x 500 mm (3036 mm) |

| Fines conveyor, L x W (discharge height) | 4200 x 1000 mm (3100 mm) |

| Swiveling recycling conveyor can be used as recycling conveyor (closed circuit) / stockpile conveyor oversize fraction (hydraulic foldable) | / |

| Walkways besides the screen box | / |

| Additional options | |

| Wheeled dolly | / |

| Dust suppression system at crusher inlet and outlet or at end of main and fines conveyo | • |

| Height adjustable magnet separator on main conveyor | • |

| Wind sifter (air knife) for oversize fraction | • |

| Dust cover main conveyor / fines conveyor | / |

| Volumetric belt scale | • |

| Radio remote, several options | • |

| Fuel filling pump | • |

| Central greasing system | • |

| Working lights | • |

| Telematics system UMTS/GPS | • |

| Heating system for engine | • |

| Lifting eyes | • |

Keestrack R3 Impact Crusher Applications

- Limestone and many other low and medium abrasive natural rock;

- Concrete and landfill recycling;

- Primary and secondary crushing;

- Yard clean up;

- Construction & Demolition waste;

- Quarrying and mining;

- Gravel;

- Asphalt;

- Coal & others.

Keestrack R3 Pros & Cons:

To provide a balanced overview, here are some potential pros and cons of the Keestrack R3 Impact Crusher:

Keestrack R3 Pros

- Innovative Technology: The Keestrack R3 Mobile Tracked Impact Crusher incorporates innovative technology, including a sustainable zero-emission plug-in electric drive system. This technology may offer environmental benefits and potentially lower operating costs over time.

- Versatile Applications: It is designed for a wide range of applications, including limestone and other natural rock, concrete and landfill recycling, primary and secondary crushing, yard clean-up, construction and demolition waste, quarrying, mining, gravel, asphalt, coal, and more. Its versatility makes it suitable for various industries and tasks.

- Compact Design: The compact design of the Keestrack R3 allows for easy transportation and maneuverability, making it suitable for various job sites and environments. Additionally, its ground-breaking design may contribute to improved efficiency and productivity.

- Maintenance Accessibility: The crusher features accessible doors and panels on all sides for maintenance and repair purposes. This accessibility can streamline maintenance tasks and reduce downtime, contributing to overall operational efficiency.

- High Safety Standards: The Keestrack R3 adheres to high safety standards, including safety protection with a special key system, emergency stops, machine stop at remote operation, and other safety features. Ensuring a safe working environment is crucial for protecting operators and minimizing accidents.

Keestrack R3 Cons

- Cost: While the innovative technology and versatile design of the Keestrack R3 may offer long-term benefits, the initial cost of acquisition may be higher compared to conventional impact crushers. However, this may be offset by potential savings in operating costs and environmental benefits over time.

- Complexity: The advanced technology incorporated into the Keestrack R3, such as the plug-in electric drive system, may introduce complexity in terms of operation and maintenance. Operators may require specialized training to fully utilize and maintain the equipment effectively.

- Dependency on Electric Infrastructure: The plug-in electric drive system relies on access to electric infrastructure for charging. In remote or off-grid locations where electric infrastructure is limited or unavailable, the operational flexibility of the crusher may be reduced.

- Maintenance Requirements: While the accessibility of doors and panels facilitates maintenance, the crusher may still require regular maintenance to ensure optimal performance and longevity. Maintenance tasks, such as replacing wear parts and conducting inspections, may add to operational costs and downtime.

- Limited Compatibility: The suitability of the Keestrack R3 for specific applications and industries may vary. While it offers versatility, there may be certain niche applications or specialized industries where alternative equipment may be more suitable.

Overall, the Keestrack R3 Mobile Tracked Impact Crusher offers several notable benefits, including innovative technology, versatile applications, and a compact design.

However, potential drawbacks such as cost, complexity, and maintenance requirements should be carefully considered when evaluating its suitability for specific needs and requirements.